7 Mistakes You're Making with PAT Testing (and How to Fix Them Before Your Next Inspection)

PAT testing isn't just another box to tick, it's your legal lifeline. Get it wrong, and you're looking at hefty fines, insurance nightmares, and potentially putting lives at risk. After years of PAT testing across Newcastle and the North East, we've seen the same costly mistakes over and over again.

Here's the thing: most PAT testing failures aren't down to faulty equipment. They're down to sloppy procedures and shortcuts that seem harmless but can land you in serious trouble.

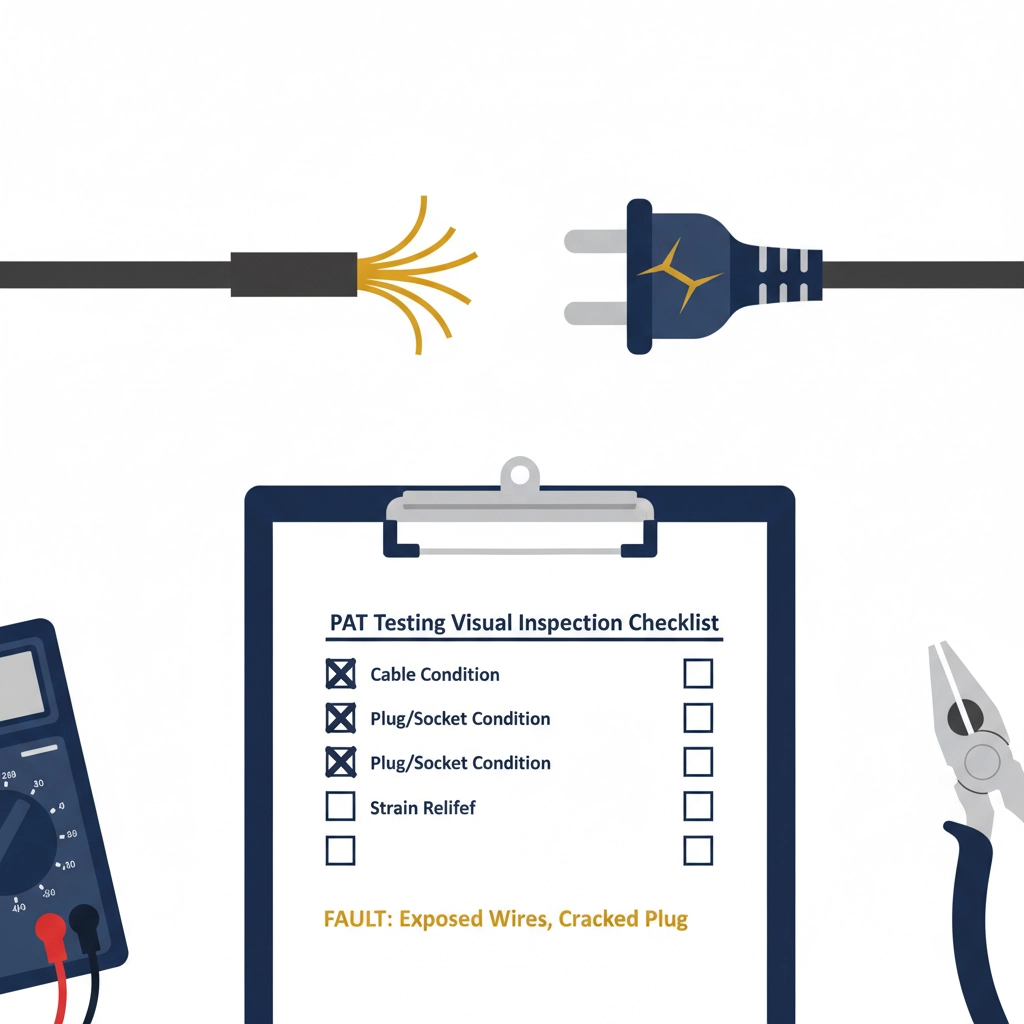

Mistake #1: Racing Through (or Skipping) Visual Inspections

Most people think PAT testing is all about plugging in fancy meters and getting readings. Wrong. The visual inspection catches more faults than all the electrical tests combined.

Yet we constantly see "PAT testing companies" who barely glance at equipment before slapping on a pass sticker. That frayed cable on your office printer? The loose plug on the kettle in your staff kitchen? These are ticking time bombs that a proper visual inspection would catch immediately.

The Fix: Start every test with a thorough visual check. Look for damaged casings, worn cables, loose connections, and signs of overheating. For rewirable plugs, you MUST open them up and inspect the wiring, terminal tightness, and fuse rating. This isn't optional, it's required by law.

Document everything. A dent might seem minor, but it could indicate the appliance has been dropped and internal damage could follow.

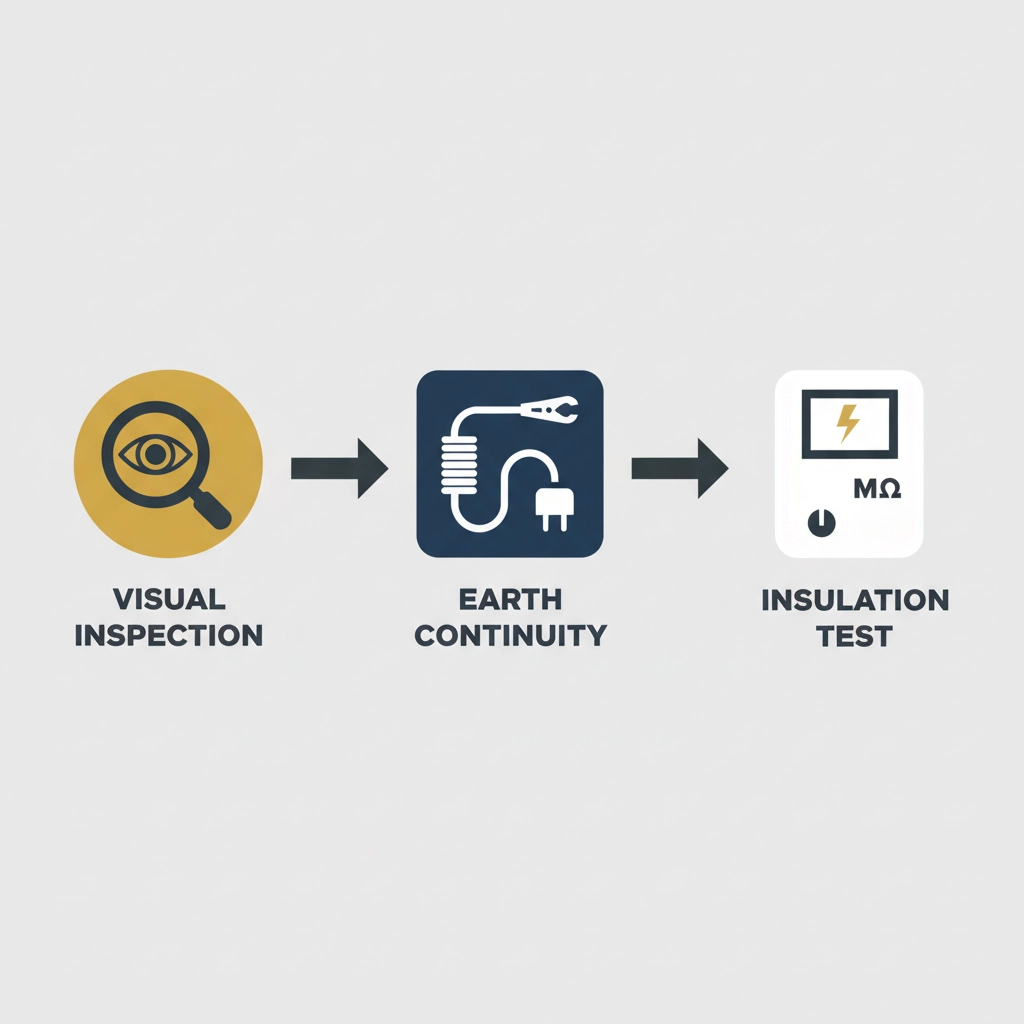

Mistake #2: Testing Equipment in the Wrong Order

This one's technical but crucial. Testing in the wrong sequence can give you false results that make dangerous equipment appear safe.

With Class I appliances (anything with an earth wire), you must prove the earth path works BEFORE running insulation tests. Why? Because most PAT testers use the earth wire as the return path for insulation testing. Test a faulty earth connection for insulation, and you'll get meaningless results.

The Fix: Always follow this sequence: Visual inspection → Earth continuity test → Insulation test. No shortcuts, no exceptions. Your PAT testing certificate is only worth the paper it's printed on if you follow proper procedures.

Mistake #3: Testing Equipment While It's Switched Off

This mistake is everywhere, and it's dangerous. When you test an appliance in the "off" position, everything beyond the switch goes untested. That faulty heating element in the kettle? The dodgy motor in the vacuum cleaner? They'll sail through testing while still being lethal.

We've seen appliances pass PAT testing with this mistake, only to cause fires or electrocutions when actually used.

The Fix: Always switch equipment ON during insulation and leakage tests. For some appliances, you'll need to manually hold the switch in the "on" position throughout testing. Yes, it's more work, but it's the difference between proper PAT testing and dangerous box-ticking.

Mistake #4: Touching Equipment During Testing

Here's a shocker: some people actually hold appliances during electrical testing to "improve contact" with test probes. This is insane. Insulation tests run at 500 volts. When you eventually hit a piece of equipment that fails the test (and you will), you'll be the one getting shocked.

The Fix: Keep your hands OFF equipment during all electrical testing. Use proper probes and test leads. Maintain safe distances. Your fingers aren't part of the testing equipment.

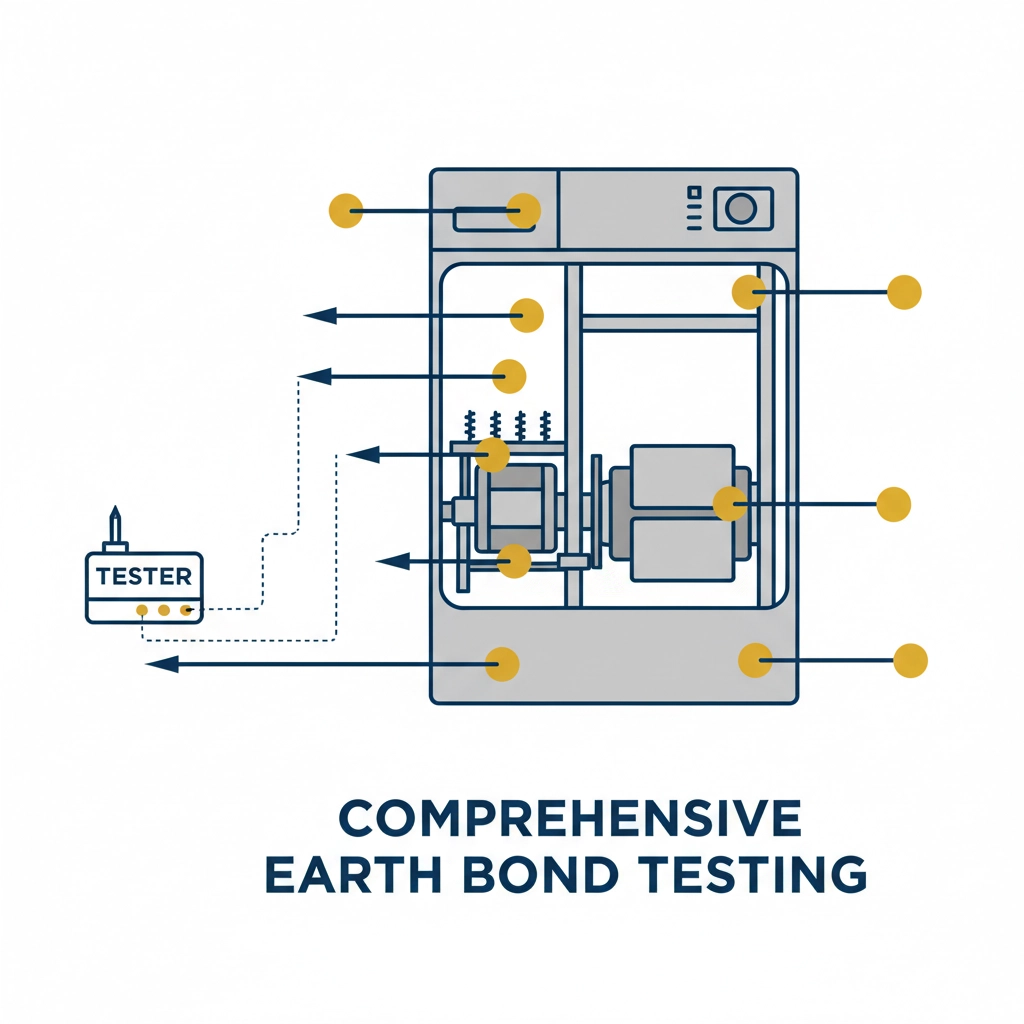

Mistake #5: Half-Hearted Earth Bond Testing

Many appliances have multiple metal parts that need individual earth bond testing. Yet we see testers who do one quick test and move on. Each exposed metal part with its own earth path needs separate verification.

Miss one, and you've left a potential death trap in someone's office.

The Fix: Identify ALL exposed metal parts on Class I appliances and test each one individually. Don't rely on early PAT tester sequences that might only check one earth point. Every metal surface someone could touch needs proper earth protection verified.

Mistake #6: Recording Average Results Instead of Worst-Case Readings

When multiple earth bond tests are needed, some testers average the readings. This is completely wrong and potentially deadly. That one high resistance reading you're averaging out? That's the dangerous one that could kill someone.

The Fix: Always record the WORST (highest) reading when multiple tests are performed. The highest resistance is what matters for safety, not some averaged-out number that hides problems.

Also, record actual measurements, not just "Pass/Fail." Real numbers provide valuable trending data and prove you actually did the tests properly.

Mistake #7: Wrong Approach to Class II Equipment

Class II appliances (double-insulated equipment marked with the square-within-square symbol) don't have earth connections. Yet we see people trying to earth bond test them, which is impossible and unnecessary.

But here's the flip side: during insulation testing on Class II equipment, you still need to connect test leads to exposed metal parts. Without this connection, you'll get false passes even when serious faults exist.

The Fix: Learn to identify Class II equipment properly. Skip earth bond tests for these items, but ensure you're connecting test leads correctly during insulation testing. The test lead creates the necessary return path for accurate measurements.

Why These Mistakes Matter More in 2025

Commercial PAT testing requirements have tightened significantly. Insurance companies are cracking down harder on inadequate testing. HSE inspections are more frequent and thorough than ever.

In the North East, we've seen businesses face serious consequences:

- £50,000+ fines for electrical safety failures

- Insurance claims rejected due to inadequate PAT testing

- Business closures following electrical accidents

The cost of getting it wrong far exceeds the investment in getting it right.

Getting Professional PAT Testing Right

If you're handling your own PAT testing, invest in proper training. If you're hiring a PAT testing service, ask the right questions:

- Do they perform full visual inspections?

- Will they test equipment in the correct sequence?

- Do they provide actual measurement readings?

- Are their technicians properly trained and certified?

For businesses across Newcastle, Gateshead, and the broader North East, don't gamble with electrical safety. The consequences of cutting corners aren't worth the risk.

Need professional PAT testing that gets it right first time? Our certified technicians follow every procedure to the letter, providing comprehensive PAT testing services that keep your business compliant and your people safe. We understand the local compliance requirements and work efficiently to minimize disruption to your operations.

Contact Nifty Fixes North East for reliable, professional PAT testing that you can trust. Because when it comes to electrical safety, there's no room for mistakes.