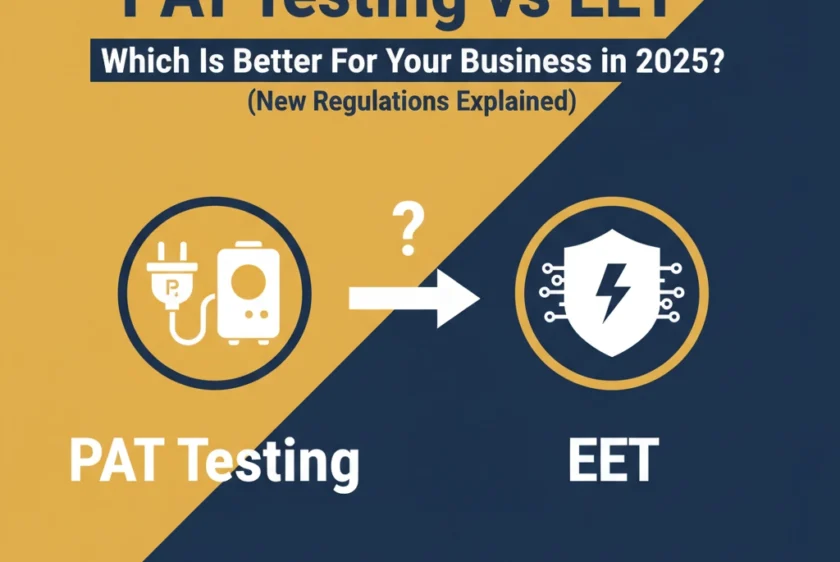

PAT Testing vs EET: Which Is Better For Your Business in 2025? (New Regulations Explained)

Here's the thing that's confusing every business owner right now: "Do I need PAT testing or EET testing?"

The answer might surprise you. They're not actually competing systems.

EET (Electrical Equipment Testing) is the updated, more comprehensive approach that's gradually replacing traditional PAT testing methods. Think of it as PAT testing 2.0 – same core safety principles, but with better coverage and clearer guidelines.

What Traditional PAT Testing Actually Covers

PAT stands for Portable Appliance Testing. The name itself creates problems.

The "Portable" Problem: Many businesses think PAT only covers laptops, kettles, and desk fans. Wrong. It includes anything that plugs into the mains – even if it's bolted to the floor.

The "Appliance" Confusion: This term makes people think of white goods like washing machines and fridges. But PAT testing actually covers extension leads, power tools, and plenty of equipment that isn't an "appliance" at all.

Traditional PAT testing has been the standard for decades. It works. But the terminology leaves gaps that can cost businesses money – or worse, put people at risk.

EET Testing: The Updated Approach

EET removes the confusion entirely. "Electrical Equipment Testing" covers everything that uses mains electricity, regardless of size or mobility.

Better Risk Assessment: EET uses improved evaluation methods that consider equipment type, age, operating environment, and who's using it. This systematic approach provides better protection than basic PAT methods.

Comprehensive Coverage: No more guessing games. If it plugs in, it gets assessed. Fixed installations, specialized equipment, items that traditional PAT might overlook – EET covers the lot.

Modern Standards: EET aligns with current IET (Institution of Engineering and Technology) Code of Practice standards, ensuring businesses stay compliant with evolving requirements.

The Legal Side: What Actually Matters in 2025

Here's what hasn't changed: the Electricity at Work Regulations 1989 still require employers to maintain electrical equipment in safe condition.

Key Point: Neither PAT nor EET testing is explicitly required by law. But regular inspection and testing is the recommended way to prove compliance.

Risk-Based Approach: You don't need to test everything annually anymore. The frequency depends on your risk assessment – equipment type, environment, and usage patterns all factor in.

Documentation Matters: Whether you call it PAT or EET, you need proper records. Inspectors want to see systematic approaches to electrical safety, not just stickers on plugs.

Which Approach Works Better for Your Business?

The honest answer: EET methodology with clear communication.

For Office Environments: EET's comprehensive approach catches more potential issues. Desktop computers, printers, phone chargers, extension leads, kitchen equipment – everything gets proper evaluation.

For Industrial Settings: The enhanced risk assessment in EET is crucial. Heavy machinery, harsh environments, and specialist equipment need more than basic PAT approaches can provide.

For Retail Businesses: EET's broader coverage ensures you don't miss critical equipment like payment terminals, display lighting, or customer-accessible charging points.

For Landlords: EET provides clearer guidance on what needs testing in furnished properties. No more arguments about whether something counts as "portable."

Cost and Efficiency Benefits

Smarter Testing Schedules: EET's risk-based approach means you're not over-testing low-risk equipment or under-testing critical items.

Better Resource Allocation: Focus testing efforts where they're actually needed. High-risk environments get more attention, office equipment with minimal usage gets appropriate intervals.

Reduced Compliance Gaps: Comprehensive coverage means fewer nasty surprises during inspections or after incidents.

Common Misconceptions Cleared Up

"EET is more expensive": Not necessarily. Better risk assessment often reduces unnecessary testing, balancing any increase in scope.

"PAT testing is being phased out": The terminology is evolving, but the fundamental testing principles remain valid.

"Only large businesses need EET": Size doesn't matter. A small café with basic equipment benefits from comprehensive coverage just as much as a manufacturing plant.

"Annual testing is mandatory": Wrong. Testing frequency should be based on risk assessment, not arbitrary timeframes.

What This Means for North East Businesses

As of September 2025, the electrical safety landscape has clearly shifted toward comprehensive testing approaches. Most professional testing companies now use EET methodology, even if they still market "PAT testing" services.

Current Industry Practice: EET terminology is increasingly standard, but both terms refer to essentially the same testing process – just with different levels of comprehensiveness.

Future-Proofing: Adopting EET approaches ensures your business stays aligned with evolving industry standards and regulatory expectations.

Practical Recommendations

Choose Comprehensive Testing: Whether your provider calls it PAT or EET, ensure they're using comprehensive risk assessment and broad equipment coverage.

Focus on Competence: The person doing your testing matters more than the terminology they use. Ensure they understand current standards and have proper equipment.

Document Everything: Maintain clear records of testing schedules, results, and risk assessments. This demonstrates systematic approach to electrical safety.

Review Regularly: Don't just book annual testing. Review your electrical equipment regularly and adjust testing schedules based on actual risk factors.

Making the Right Choice

For businesses operating in 2025, the choice isn't really between PAT and EET – it's about adopting the most current and comprehensive approach to electrical safety.

EET methodology provides better coverage, clearer guidance, and improved risk assessment. It's the evolution of PAT testing practices, offering everything traditional PAT provided plus modern improvements.

Bottom Line: Work with testing providers who understand current standards and use comprehensive approaches, regardless of what they call the service.

If you need professional electrical equipment testing that covers all bases, get in touch with our team. We use current EET methodology to ensure your business stays safe and compliant – no confusion, no gaps, just comprehensive electrical safety testing that actually protects your people and property.

Don't let outdated approaches or terminology confusion leave your business exposed. Modern electrical safety testing should be comprehensive, risk-based, and properly documented. That's what EET methodology delivers.